Living Room Paint Colors Ideas Gray And White Trim

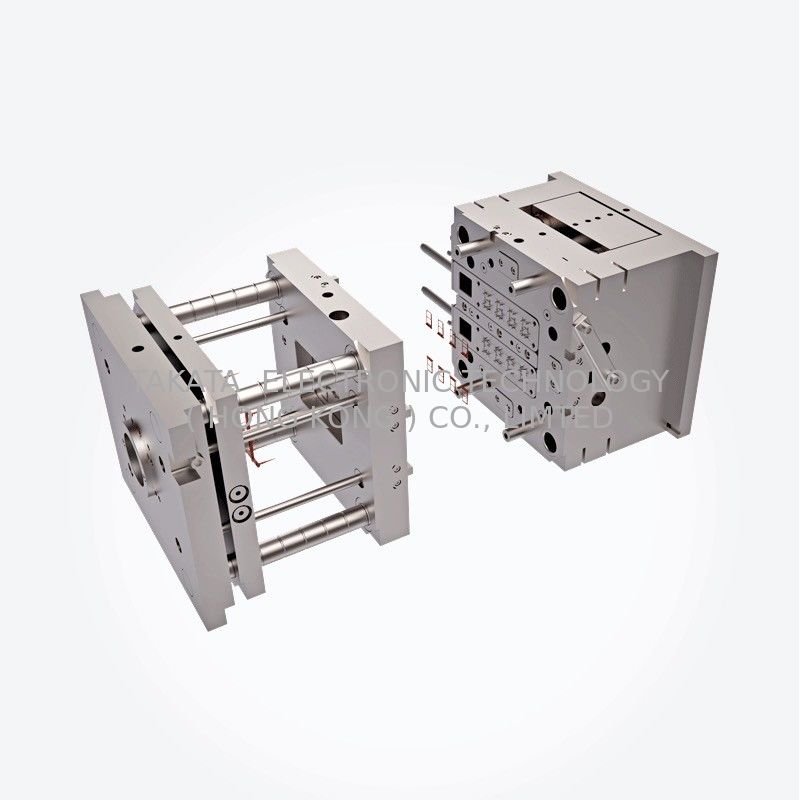

The video is provided by the engineers of Elimold Company. It mainly demonstrates one of the design methods of our two-color mold, and the actual working pro.

Wooden Moulding F4820.470

Figure 2: 2 shot injection molding process. The second phase uses a robotic arm to place another layer of plastic on top of the first one. The two plastics materials can differ in color, texture, and hardness. This process mainly creates products with two or more different colors or materials. For example, a product with a hard outer shell and.

Wooden moulding Z591P/01

99% we injection hard material first, before soft is easy to deform. In order to make the two plastic stick more tightly, we should consider "sticky" of two resin and the roughness of mold surface. .two color mold have another name "two-shot mold", they inject two resin on the same machine but injection two times, typically consist of 2.

Chair Rails, Baseboards, and Other Moldings My Ideal Home

Introduction to Multi-Shot Injection Molding. Multi-shot injection molding, also known as multi-color injection molding, refers to the process where two or more colors or different materials are molded using a mold with one or more channels. Historically, dual-color injection molding was the pioneer in this field.

Can Crown Molding and Baseboard be Different Colors?

Two-color / Two-shot injection molding, also known as bi-color, multi-shot, bi-injection molding or double-shot molding and 2k injection molding is a subcategory of injection molding that allows to inject two kinds of the same material or two different material (PP+PP,PC+PC,PP+TPE) through one injection molding machine (two color injection.

Our 6 Most Popular Moulding Profiles Horner Millwork Crown molding, Moldings and trim

DOUBLE COLOR INJECTION MOULDING MACHINE PROCESSHere we have presented animation of Double color injection molding process animation for easy understanding

Wooden Moulding M7902.982

Two-color injection molding is a multi-material injection molding process. The molded plastic part can be a combination of two different materials or a combination of different colors of the same material. Two-color molding can also be called 2k injection molding, double shot molding, multiple injection molding (sequential injection molding).

multi colour moulding examples Eastern Plastics Injection Moulding and Hot Runner Solutions

What is a two-color injection molding machine. As the name suggests, it is an injection molding machine that can process two colors of plastic materials at the same time. It usually has 2 injection units, processing one material at a time. These two materials can be injected at the same time or at different times according to product requirements.

Nick Moulding

Narrowly speaking, two-color injection molding is the use of a two-color injection molding machine, two different plastics in the same machine injection molding to complete the parts, the common is the rotary type. The former does not require high equipment requirements, but the production efficiency is low, basically only applicable to the.

Matt Moulding The Moulding Foundation

Two-Color Molding may also be referred to as: 2-Shot molding, Bi-injection molding, Co-injection Molding, or Multi-Shot Injection Molding. This technology produces a part with two different colors and/or materials in a single operation. The machine has two injection units: one vertical and one horizontal. By using a rotating mold, the machine.

Roof Moulding Autoretails

Two-color injection molding, also known as bi-color or two-shot injection molding, is a manufacturing process that involves injecting two different materials or colors into a single mold to create a single part. This advanced injection molding technique offers many benefits and is widely used in various industries, including automotive, medical.

Pin by Kelly Wayne on House Ideas House design, House interior, Home

Two-Shot Molding (also called 2k mold, double injection molding) are a cost-effective method to produce plastic parts with two or more colors moulded at the same time, such as radio control buttons or dashboard faceplates. Two-Shot molding is a relatively new, rapidly growing technology.

Wooden Moulding M5753.617

Producing two color or two component injected molded parts from two different thermoplastic materials in one process, quickly and efficiently:Two-shot plasti.

Polyethylene Two Colour Injection Moulding

Injection moulding is a very useful manufacturing procedure for mass production of goods with similar shapes. Giving different aesthetics by introducing a variety of colouring options is a difficult and time-consuming process.This problem has been completely eradicated by two-color injection molding.It enables professionals to manage product moulding with two separate materials and colours.

+/0.03mm Polypropylene Two Colour Injection Moulding

A two-color injection molded product features a high quality stability, making it easy to control product deformation, reduce the molding cycle, and increase the output, with a scrap rate 7% lower than that of overmolding, and a product manufacturing cost 20%-30% lower than the latter. II. How Two-color Molding Works.

Wooden Moulding 16/ARG

The benefits of the process include: Intricate parts: 2-Shot molding enhances your design options, making it possible to create detailed parts designs that are durable, functional and aesthetically appealing.The process combines multiple materials, product features and/ or colors to create parts or products that are difficult to achieve with other manufacturing techniques.